A few months ago, we released our 2014 Manufacturing ERP Report, which summarizes our research and experience related to the unique challenges the manufacturing industry faces when implementing ERP software. Due to the inherent complexity of manufacturing processes, ERP implementations in the manufacturing industry often involve extensive customization and technical integration. As a result, these implementations also tend to be over-budget and over-schedule.

Here are a few highlights of our 2014 Manufacturing ERP Report:

ERP implementation costs and durations are increasingly hard to predict. As revealed in our report, manufacturing ERP implementations actually have the biggest delta between planned and actual implementation durations, with companies implementing in an average of 18.5 months compared to an expected duration of 14.7 months. Across all industries, expected durations average 19.3 months while actual durations average 19.1 months. Manufacturing organizations also experience gaps between their actual and expected implementation costs, with the average manufacturing ERP implementation running $3 million over budget, and the average ERP implementation across all industries running only $1.7 million over budget.

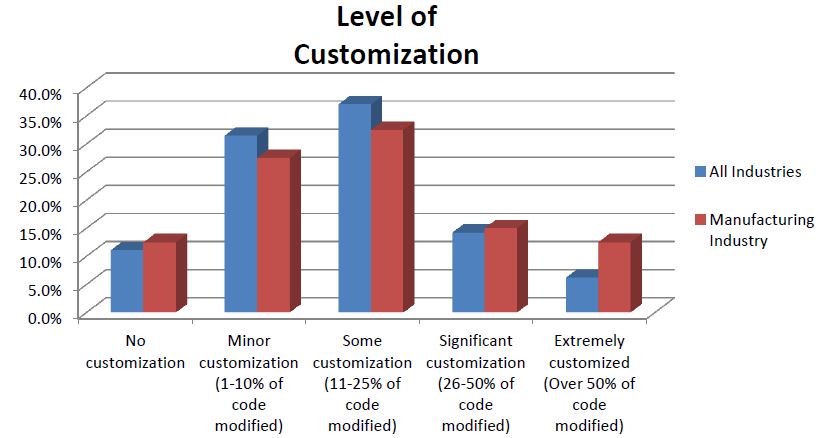

Customization tends to increase implementation risk. Based on data revealed in this report, CIOs and CFOs would be well-served to plan ahead in order to mitigate the risks of cost and duration overruns. Our data reveals that the level of customization in manufacturing ERP implementations is slightly higher when compared to all industries as a whole. While 13% of manufacturing organizations implement ERP without customization, 11% of organizations across all industries implement without customization. In addition, manufacturing organizations are twice as likely to experience heavy customization compared to other industries. As outlined in the report, this high level of customization is related to the high degrees of specialization and complexity inherent in many manufacturing organizations.

Increased time and money does not always result in increased benefits. While our report shows that manufacturing organizations spend more time and money on their ERP implementations compared to other organizations, manufacturing organizations do not achieve more business benefits. According to our findings, 40% of manufacturing ERP implementations realize 0-30% of anticipated benefits and only 13% realize 80-100% of anticipated benefits. When adequate time and money is invested in organizational change management and business process reengineering, high benefits realization will likely follow, but many manufacturing organizations allocate the majority of their budget to the technical aspects of the project and neglect the “people” side of their ERP implementation.

These are just a few of the themes and trends we see in the report. While our quantitative and qualitative research isn’t meant to provide all answers related to manufacturing ERP implementations, it is intended to provide an important data point during our clients’ ERP selection and implementation planning processes.

Learn more by downloading our 2014 Manufacturing ERP Report and our related on-demand webinar.